BLACKYAK TECHNOLOGIES

-

OUR PARTNERS

-

To implement our technologies, we use the most innovative materials on the market. Our partnerships with manufacturers and producers are therefore especially important to us and we are happy about our high-quality network in the outdoor industry.

Products engineered with GORE-TEX fabric are durably waterproof and windproof, combined with optimized breathability — enduring products that maximize protection and comfort for the wearer. All GORE-TEX products are covered by the GUARANTEED TO KEEP YOU DRY™ promise.

The GORE-TEX INFINIUM™ WINDSTOPPER® product technology collection offers totally windproof and breathable apparel. Designed for flexibility, functionality and style to support your active life – when comfort and performance are the priority, and waterproofness isn't.

RECCO® technology is a tool for professional rescuers to help locate buried victims, enabling professional rescuers to find victims within minutes.

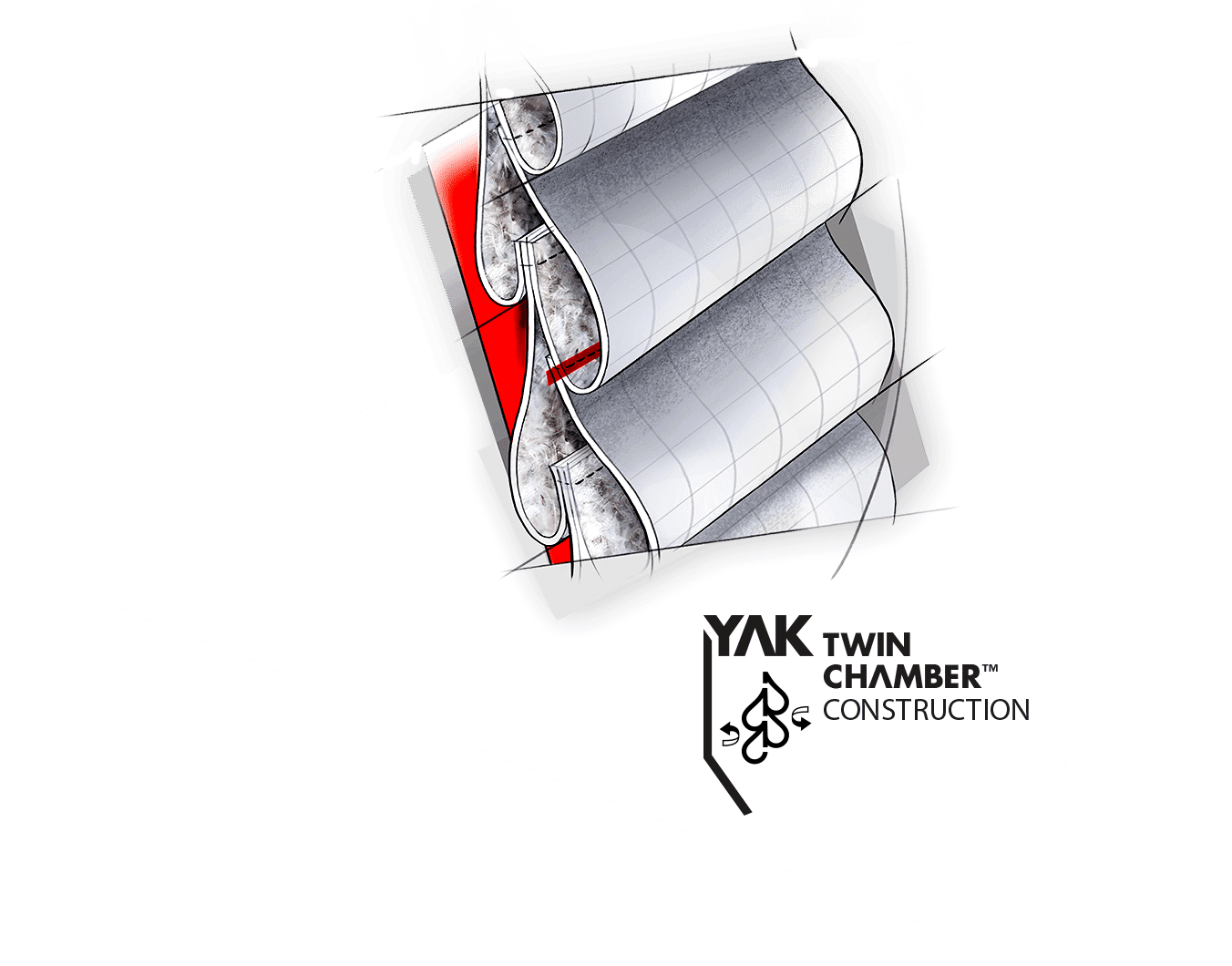

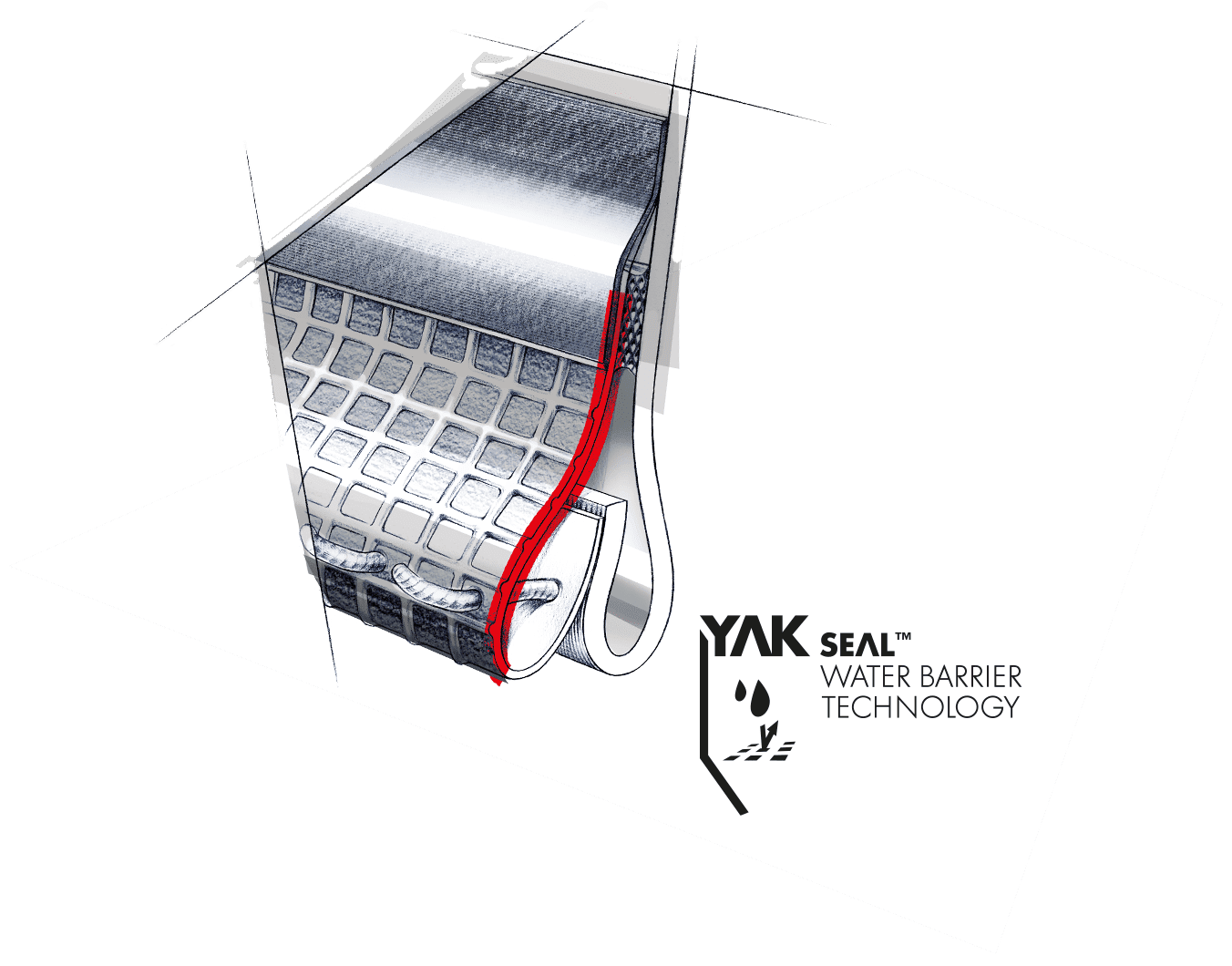

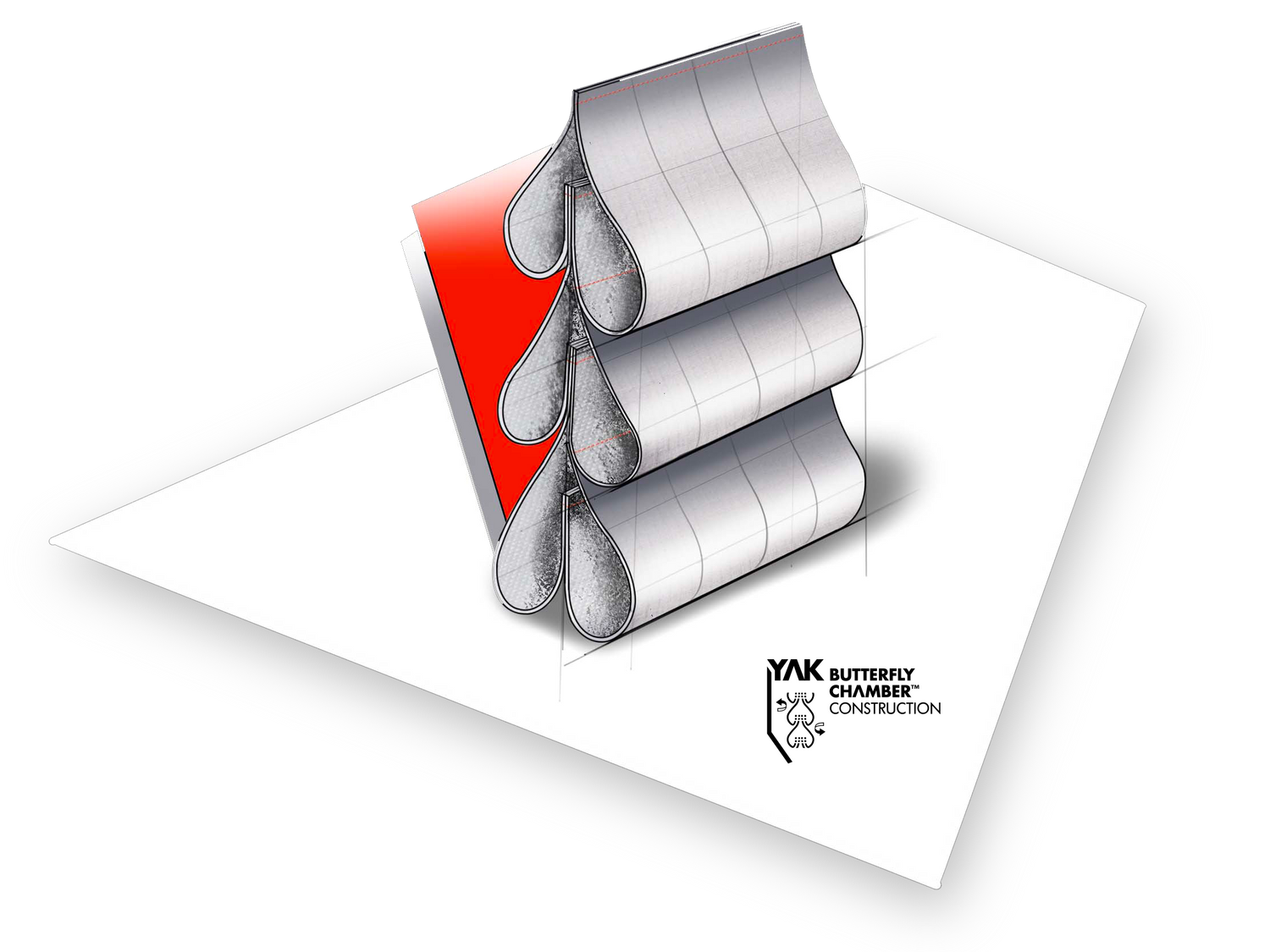

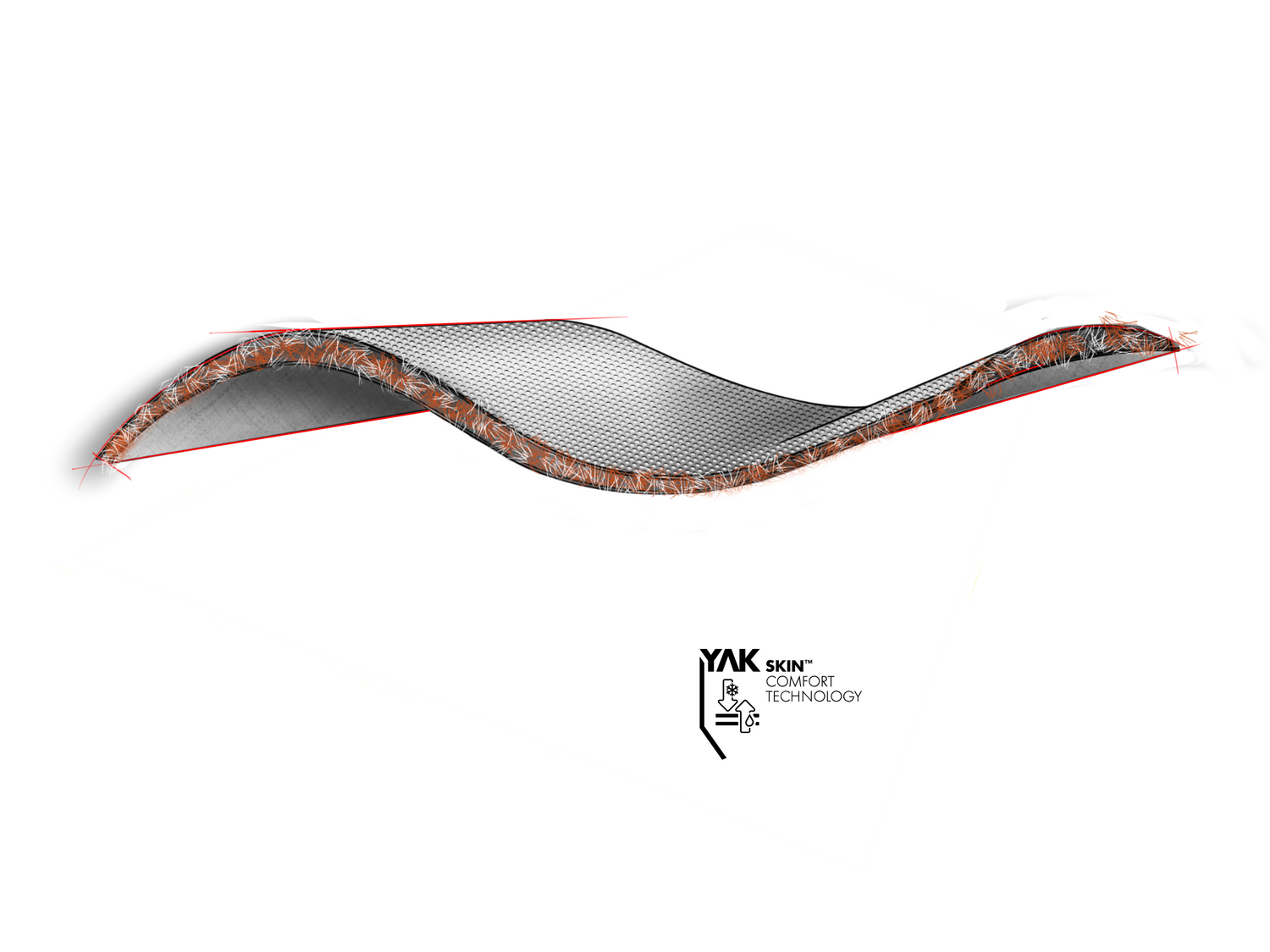

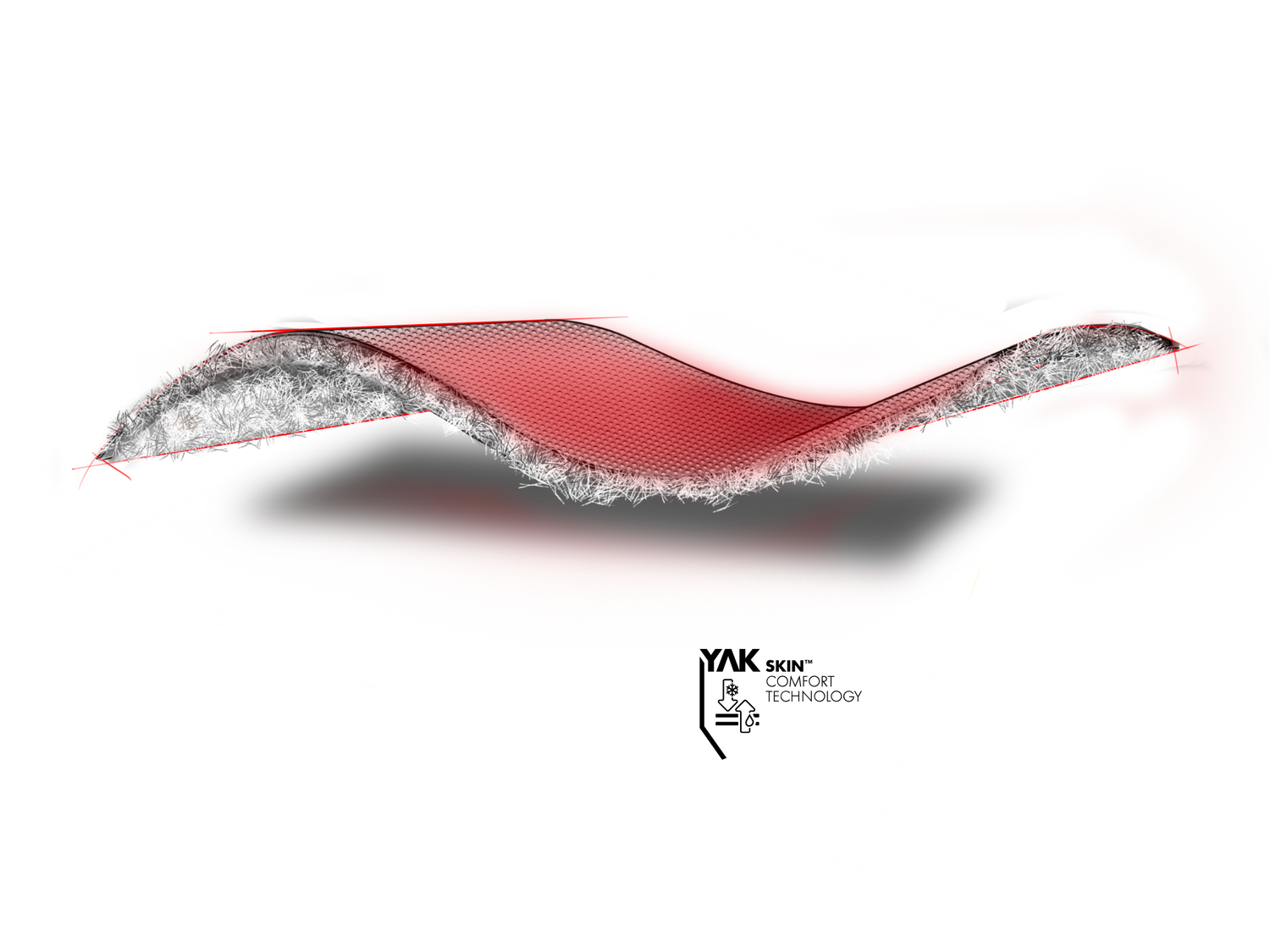

Warm, light and breathable - even in extremely wet and cold weather: the revolutionary G-LOFT® insulation meets the highest standards and combines the benefits of natural down with the ruggedness of a synthetic fibre.

Re:Down® recycles down and feathers extracted from post-consumer goods so that they can be reused as filling material in apparel, sleeping bags or bedding products. Broken feathers and down fibers are upcycled into a very efficient organic fertilizer.

CORDURA® is the brand name for a collection of fabrics used in a wide array of products including luggage, rucksacks, pants, military wear and performance apparel. CORDURA® fabrics are known for their durability and resistance to abrasion, tears and scuffs. CORDURA® fabrics are usually made of nylon but may be blended with cotton or other natural fibers.

Kevlar® fiber is used to make a variety of clothing, accessories and equipment safe and cut resistant. It's lightweight, durable and extraordinarily strong. It's best known for its use in ballistic and stab resistant body armour. But it's also used on the ski slopes, the switchback trails, in demanding desert terrain, even the outer limits of space.

PrimaLoft® is a synthetic microfibre thermal insulation. PrimaLoft® insulation is used inside insulated garments for its warmth, compressibility and soft comfort. While the human body uses energy to stay warm, PrimaLoft® insulation uses a proprietary microfibre structure to help the body retain warmth and conserve energy.

With a wide variety of different materials and textiles, Polartec® offers the possibility to meet demanding outdoor challenges with fun and energy – even in bad weather.